Technical Info

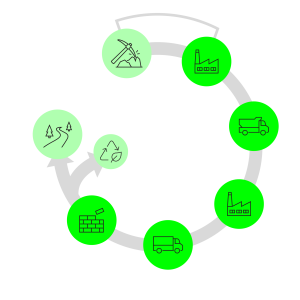

1) Life Cycle Analysis

We have commissioned rigorous a life cycle analysis, carried out by Encon, a highly respected independent consultancy supporting businesses in the transition to sustainability.

THE LCA HAS BEEN VERIFIED BY AN EXTERNAL ORGANISATION, APPLYING FOLLOWING STANDARDS:

GHG PRODUCT LIFECYCLE STANDARD

ISO 14044 STANDARD

CRADLE-TO-GRAVE APPROACH

CARBON FOOTPRINT OF LOWIE BRICKS

The whole life carbon emissions of 215 x 65 x 102.5mm Lowie bricks come to 10.85KgCO2/m² representing a 76.1% reduction compared with kiln fired clay bricks. An even greater reduction of up to 81.3% can be achieved using a module with a depth of 80mm, available in several formats. The reduction in carbon emissions is driven by 2 key factors –

1) The vibro-press production method eliminates the need for high heat gas ovens and heated curing rooms, vastly reducing the initial production emissions

2) Maximising natural carbonation Carbonation is the process by which weaker hydroxide molecules within the brick, bond with atmospheric CO2 resulting in the formation of strong carbonates. Lowie bricks are designed with high levels of air diffusivity to encourage the acceleration of this process. Most of the embodied carbon emissions of a Lowie brick come from the binders, which are a by-product of the steel industry – when full carbonation has taken place, 58% of the binders carbon emissions have been recovered, and unlike biological carbon capture, this method of storage is permanent. Put in simple terms, a building built in Lowie bricks will continue to absorb CO2 from the air for a period of up to 30 years. After this time, the process is complete.

2) Co2 Reduction Calculator

| CO2 Reduction (Tonnes) |

|---|

| 0.00 |

3) Carbon Footprint Certification

Please see below Certification of Carbon Footprint, awarded by Encon, who conducted the life cycle analysis on Lowie Bricks

The life cycle analysis includes all carbon emissions – from extraction of the raw materials & production, throughout the functional lifetime of the bricks, when CO2 is captured from the atmosphere, and stored through natural carbonation.

4) Lowie VS Traditional Facing Bricks

PLEASE NOTE: THE BELOW TABLE PROVIDES A GENERAL OVERVIEW. VARIATIONS CAN OCCUR BASED ON SPECIFIC MANUFACTURING PROCESSES AND COMPOSITIONS. DIFFERENT MANUFACTURERS MAY PRODUCE CONCRETE OR CLAY BRICKS WITH VARYING SPECIFICATIONS.

| LOWIE FACING BRICKS |

SOFT MUD CLAY FACING BRICKS |

CLAY WIRE-CUT FACING BRICKS |

CONCRETE BRICKS |

|

|---|---|---|---|---|

| European Standards | EN 771-1: Part 1: Clay masonry units EN 771-3: Part 3: Aggregate concrete masonry units |

EN 771-1: Part 1: Clay masonry units | EN 771-1: Part 1: Clay masonry units | EN 771-3: Part 3: Aggregate concrete masonry units |

| Compressive Strength | ≥ 20N/mm² | ≥ 10 N/mm² – 25N/mm² | ≥ 30 N/mm² – 65N/mm² | ≥ 2 N/mm² – 40N/mm² |

| Water Absorption | <14% | <10-25% | <6-16% | <5-9% |

| Size Tolerance | T2 | TM, T1, T2 | TM, T1, T2 | D1, D2, D3 |

| Composition | Natural sands and minerals, sustainable binders | Excavated clay, sand and additives | Excavated clay, sand and additives | Produced from naturally occurring aggregates, portland cement, various admixtures and supplements |

| Durability | F2 | F0, F1, F2 | F0, F1, F2 | C7-C15 (F0), C16-C21 (F1), C22+ (F2) |

| Soluble Salts | S2 | S1, S2 | S1, S2 | N/A |

| Fire Rating | A1 | A1 | A1 | A1 |

| Thermal Conductivity | 0,62 W/m*K | 0.4-1 W/m*K | 0.4-1 W/m*K | 1.11 W/m*K |

5) Technical Data Sheets

Download the data sheets for all out bricks below.

6) Movement Joints

Lowie bricks, with their unique composition, experience a different rate of hygrometric shrinkage and expansion compared with clay bricks.

This means that vertical movement joints are required every 6 meters with Lowie bricks, although this can be extended to every 8 metres under certain conditions. This is the same as the requirement for concrete bricks, whereas with clay bricks they are required every 10-12 metres.

| TYPE OF MASONRY | DISTANCE BETWEEN EXPANSION JOINT BY EUROCODE 6-2 | HYDROMETRIC SHRINKAGE / EXPANSION |

| LOWIE BRICK | 6-8 M | ≤0.45 MM/M |

| CONCRETE BRICK | 6-8 M | ≤0.45 MM/M |

| CLAY BRICK | 10-12 M | ≤0.1 MM/M |

Horizontal Movement Joints

With standard clay bricks, for buildings over 12m in height, horizontal movement joints should be included every 2nd or 3rd storey, depending on the design. For Lowie bricks, horizontal movement joints are required every 2nd storey for buildings over 9 metres in height.

For more detailed guidance on movement joints, please refer to document PD 6697 to fulfil Eurocode 6.

Free Consultation Service

Lowie offer a free consultation service regarding the positioning of movement joints.

Our in-house structural engineers are trained to provide expert advice on the placement of movement joints, considering the aesthetic impact as well as the technical requirements.

We recognise that no project is the same – whether the preferred approach is to disguise movement joints, or to incorporate them into the facade, our experienced team are on hand to provide guidance tailored to support and enhance the overall design.

Disguising Movement Joints – Colour Matching Sanded Silicone

Movement joints can be made to blend in with standard mortar joints by filling the gap with a colour matching silicone. Lowie have partnered with OTTOSEAL, suppliers of premium construction silicon products, & together we have devised a selected range of sealants (S110) to complement all of our portfolio. With so many shades available, we are able to provide a match for any mortar colour specified.

Ottoseal also offer a structured silicone (M361) which contains sand mixed in with the silicone, which offers an even closer aesthetic to mortar.

The below picture demonstrates how the use of Ottoseal (M361) silicone can make the movement joint indistinguishable.

Please speak to a member of our team for further information